|

Our Products

|

Conversion Kit for- your existing Analogue & Old Computerized Model

Up Gradation Of Universal Testing Machine!

In the wake of technological advancement and automation, existing mechanical dial type Universal Testing Machines are getting obsolete. Moreover it takes plenty of time for testing. Plotting of graph of required test in different units is still more difficult. Evaluation of important parameters like Proof stress, Young's modulus is very tedious and time consuming.

FASNE TEST EQUIPMENT PVT. LTD, has developed the most user friendly and precise Electronic Measuring System for Universal Testing Machines.

Advantages of Electronic system

- Machine becomes computerized with digital indication of load.

- Results available in required SI units along with graph.

- Highly accurate, no manual intervention, error free working.

- Direct values of UTS, yield stress & 0.2% proof stress available.

- Customized printing / result format on computer.

We can undertake up gradation of any make machine provided that the existing machine is in working condition. The power pack, crosshead movement, jaws, inserts, and all such components / assembly should be in working condition.

After the upgradation of machine into computerized version, the accuracy of the machine will remain same as that of before

Up Gradation Package

|

|

|

|

|

|

|

| Microcontroller based Data Acquisition System (DAS Panel) |

|

Precision strain gauge based Pressure transducer |

|

Rotary Encider for measuring displacement with o.1 mm reolution |

|

Cables and pipe fittings |

|

|

|

|

|

|

|

| manual Direxction contril valve (D C valve) |

|

Electronic Extensometer (Model:fff-5) |

|

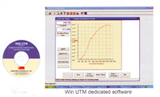

Win utm dedicated software |

|

|

Features of Microcontrolled based DAS

- Accurate, Rugged, Reliable and User Friendly system,

- Supports Tensile, Compression, Bend and other tests.

- Over load safety provided.

- Over travel safety provided.

- Auto-detection of Over-Load, Over-Travel and Specimen Break. On detection of any of the above conditions, the machine is automatically switched OFF.

- Load Resolution of 0.01 % of machine capacity for the entire measurement range.

- Elongation is indicated with a resolution of 0.1 mm.

- Tare load and Reset Elongation facilities available.

- Storage space to store data of ONE off-line test.

- Inbuilt power on self test.

- Built in Centronics Interface for Dot Matrix Printer.

- Serial RS232C Interface provided to connect to PC containing Win UTM Software.

- Two 16 character x 2 line LCD displays for displaying load and cross head travel.

Features of Direction Control Valve

Manual direction control valve directs oil flow either to pressure transducer

for computerized mode or to the existing dynamometer system for analogue mode.

Features of the Win UTM software

- Windows based User friendly software loaded on a PC with SVGA Monitor for display of data, results, graphs, etc. wOnly a serial cable from data acquisition system to PC. No additional add on cards required.

- Auto detection of over load, over travel and specimen break. On detection of any of the above conditions, the machine is automatically switched OFF.

- Load is indicated with a resolution of 0.01 % of machine capacity for the entire measurement range.

- Elongation is indicated with a resolution of 0.1 mm

- On Line graph in auto scaled mode. Selection for type of On line graph.

- Large storage capacity for storing data of minimum of 50000 tests on PC.

- Extensive range of Data Entry for easy Test Set up.

- Units interchangeability for input and results as per standards.

- Provision for calculation of parameters such as loads and Elongation at yield, peak and rupture or specimen break, yield stress, ultimate stress, etc.

- Parameters to be calculated can be selected by the operator.

- Test conditions, test data, test results are stored in a file based on unique file structure. The file name is generated from the data on which the test is conducted & the number of tests conducted on a particular date.

Each file has a unique file name.

- Extensive File handling for data storage, for selecting or generating files, feeding specimen details and test condition, viewing test graph and results etc.

Requirement of Extensometer in Universal Testing Machines

- Tension tests provide information on the strength and ductility of materials under uniaxial tensile stresses.

- Testing machines usually are equipped with wedge grips..

Elongation (or strain) values, when indicated by measuring the crosshead travel, are not accurate due to the following reasons

- Slipping of the tensile test specimen in the wedge type grips.

- Sliding down of the wedge type grips on load

- Elongation of the specimen over its entire length including within the grips and not just between the gauge length marks.

- Deflection of machine components.

This is because one is measuring the cross head travel.

Hence the measured strain values are totally inaccurate.

- To measure the correct strain values within the gauge length marks, extensometers are used.

- It is very important to ensure that maximum data is collected from the tensile test from the start of the test accurately until the yielding of the specimen has taken place.

- Using an Extensometer one can very accurately measure the strain and hence correctly determine the yield strength, Youngs' modulus and additional parameters like upper yield strength, lower yield strength, yield point elongation, etc.

- For determining the percentage elongation a nominal gauge length of 5.65 times the square root of cross sectional area of the specimen is used.

- Extensometer gauge lengths are equal to or shorter than the nominal gauge length of the specimen.

- Extensometers are used to determine the Yield Strength and Young's Modulus. Hence the extensometer gauge length I, should be less than the nominal gauge length of the specimen but greater than the specimen diameter

(specimen width for flat specimen).

- For specimens without a reduced section (for example, full cross sectional area specimens of wire, rod , or bar),

the extensometer gauge length for the determination of yield behavior shall not exceed 80% of the distance between grips.

- For additional information one can refer the standards ASTM E8, ASTM E83, IS 12872.

Features of Electronic Extensometer

FASNE offers Electronic Extensometer Model :FEE-5 to measure material extension with a resolution of one micron. Strain Gauge based extensometer is to be used up to elastic limit to determine parameters like 0.1% to 1% Proof Stress and Youngs' Modulus.

Extensometer Specifications

| Two fixed Gauge lengths |

25 mm and 50 mm (other gauge lengths - Optional) |

| Maximum Extension |

5 mm |

| Resolution |

1 micron |

| Specimen Diameter |

0.5 to 30 mm |

| Specimen thickness |

< 30 mm |

| Specimen width |

< 30 mm |

| Conforms to |

IS : 12872- Class I |

Note: Personal Computer for on line computation with computer table (it is to be supplied by customer).

Minimum computer specifications

INTEL PENTIUM IV processor, 1.8 GHZ, 256 MB DDR RAM, 40 GB HDD, Intel 845 GV chipset mother board, Win-XP OS, Multi Media Key board, 15" CRT Color Monitor, CD ROM drive, Mouse (PS2 or Optical), 1 Serial and 1 parallel port.

|